|

Centroid CNC Email News March 2025

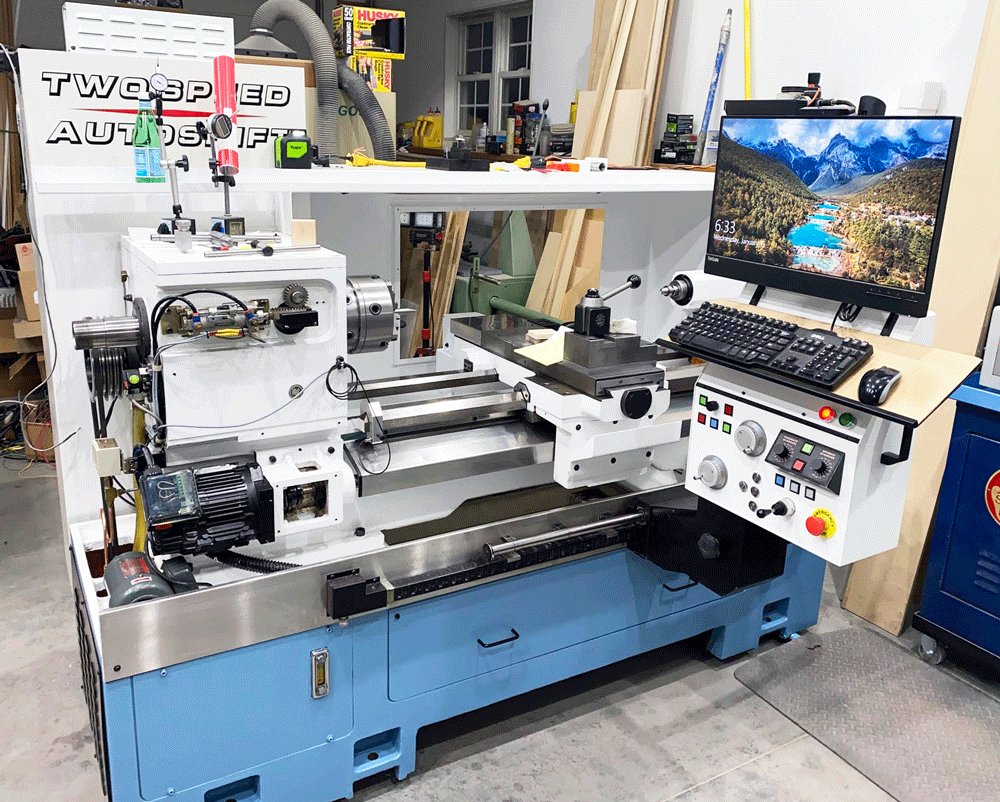

“Fryer ET-18 Easy Turn” Retrofit with an AcornSix and USB-BOB.

This “Fryer ET-18 Easy Turn” Lathe finally lives up to its name with a new

Centroid AcornSix and a

USB-BOB operator control panel,

control system built by Angelo DiCenso.

The Centroid CNC USB-BOB is an Operator Control Panel Interface Kit designed to simplify and enhance the construction

of CNC machine tool operator control panels with direct connections for operator panel buttons, joy sticks, MPG wheels,

digital encoder knobs. It serves as an affordable and reliable alternative to traditional methods of building CNC control

consoles by providing a pre-configured, plug-and-play solution that connects to a CNC PC via a USB port.

Click here to view the Photo Gallery

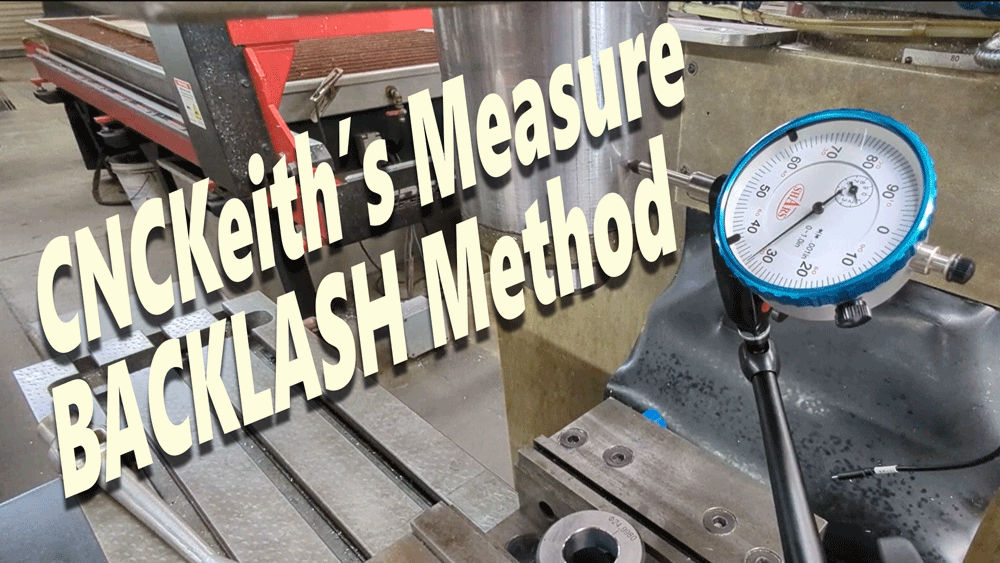

CNCKeith's Method for Measuring Machine Tool Axis Backlash

About Backlash

Centroid CNC backlash compensation is a feature used in CNC (Computer Numerical Control)

machines to improve accuracy and precision during machining operations. Backlash refers

to the small amount of play or lost motion that occurs in mechanical systems, like the

ballscrew support bearings, ball nut connections, axis motor pulleys, or other components

of a CNC machine, when the direction of movement changes. For example, when a motor reverses

direction, there can be a slight delay or looseness before the tool or workpiece actually

begins moving in the new direction. This can lead to errors in positioning and affect the

quality of the machined part.

Centroid, incorporates backlash compensation into its CNC12

software and controllers to counteract this issue. The user enters the amount of backlash

in the machine—typically in units like thousandths of an inch or millimeters—and then CNC12

automatically adjusts the movement commands to account for it. Essentially, when the machine

changes direction, the controller adds extra movement to "take up" the slack before proceeding

with the programmed path. This ensures the tool follows the intended trajectory more accurately.

In practice, backlash compensation is set up during machine calibration. The operator or technician

might run tests to determine the backlash in each axis (like X, Y, or Z), and those values are

entered into the Centroid control system. Once configured, the compensation runs seamlessly in the

background, making real-time adjustments as the machine operates.

Watch the video here!

AvidCNC, Centroid CNC Surfboard: Cutting machine walk-around tour and interview with shop owner

Watch the walk-around tour and interview here!

Part 3 of Uwe's video mini series showing the final machining of the Radial Engine Cylinders! Rigid Tapping M3 threads and Boring the liners

Watch Part 3 of Uwe's video here!

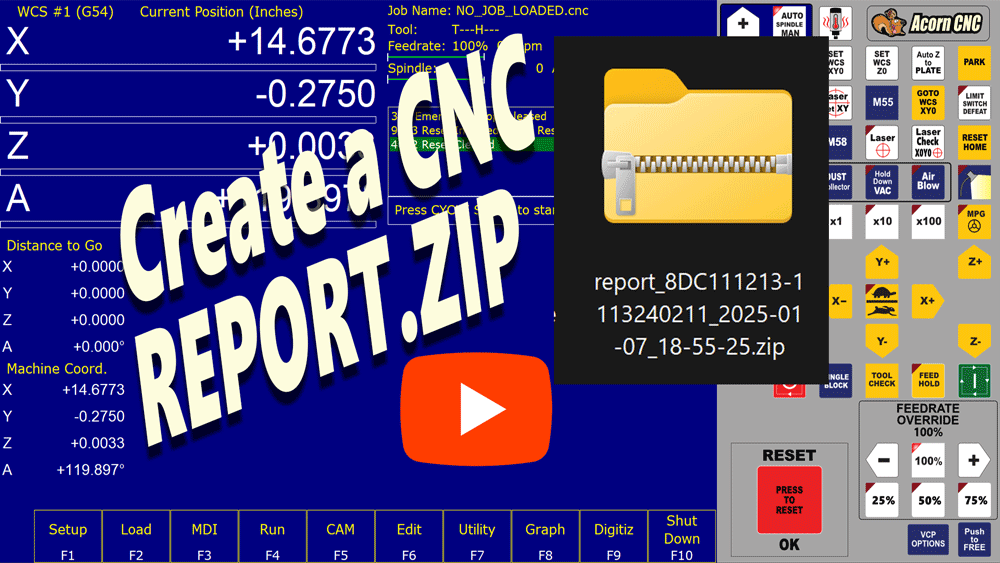

How to Create a Centroid CNC System “report.zip” file video

Click here to watch this short video!

Centroid CNC12 Version 5.28 has been released!

Available at no charge, all previous license files file work with this new version of CNC12 software

(in their respective categories: Acorn mill licenses work with Acorn mill, Oak lathe licenses work with Oak lathe CNC12, etc.)

Note: For Acorn/AcornSix/Hickory DO NOT use “restore report” with a report file from an earlier version of CNC12.

Please Follow the installation and 'upgrade' instructions found on the downloads page.

Click here to for the software download, install instructions, and the release notes for v5.28.

|