|

Centroid CNC Email News May 2025

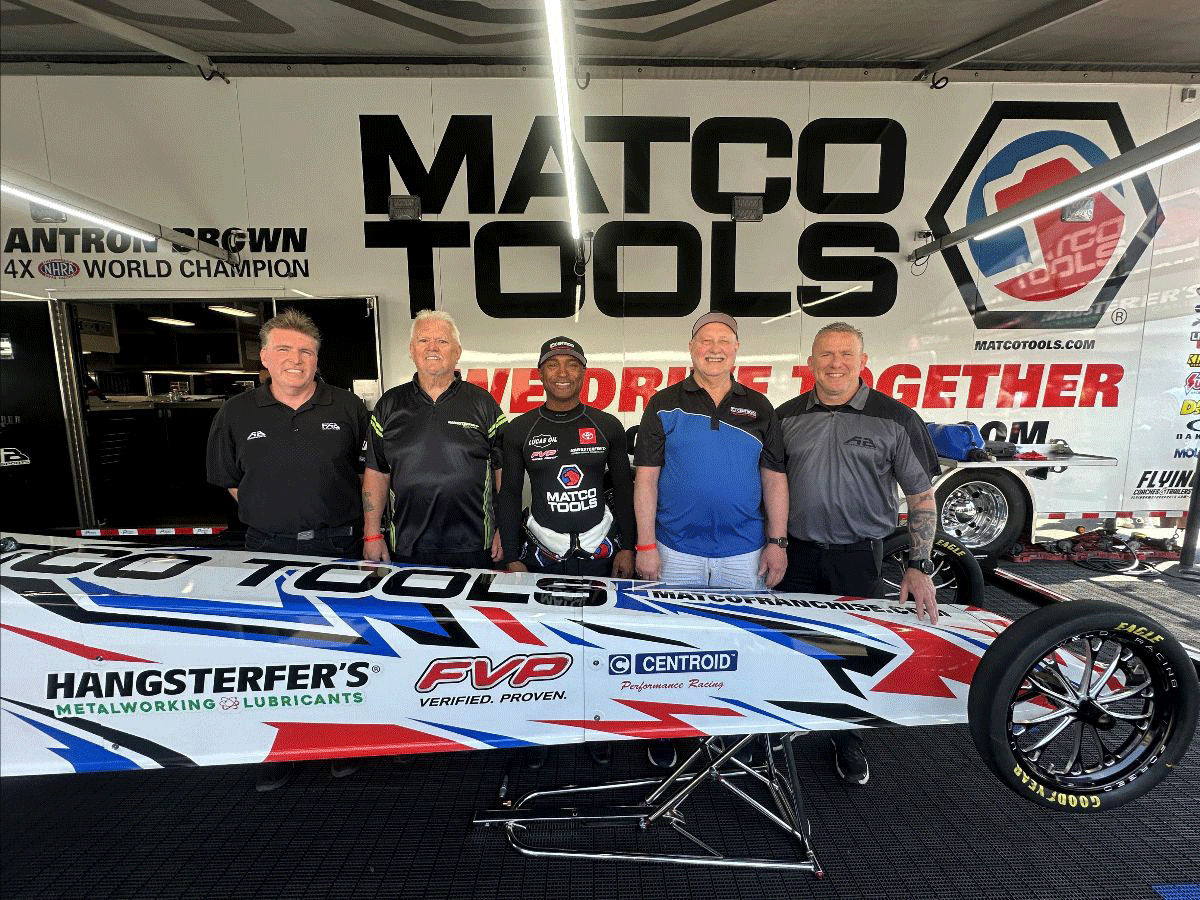

AB Motorsports and their FAB Machining division have partnered with Centroid Performance Racing!

BROWNSBURG, Ind. (May 6, 2025) – AB Motorsports and its FAB Machining division have partnered with Centroid Corporation’s

Centroid Performance Racing Division for the addition of a Centroid 5-Axis CNC Machining Center that will operate from the team’s central

Indiana race shop, team owner and four-time NHRA world champion Antron Brown announced.

Click here to read the full Press Release

“No regrets, no looking back!” — CNC Routing and Laser Engraving with the Centroid Acorn CNC Controller.

We recently caught up with Scott Worden to see how things have been going, Scott was an early adopter of the Centroid Acorn CNC controller starting

with converting his ShopBot CNC Router to the Centroid Acorn CNC controller in 2019 and then converting his Techno bench top router in 2021.

Scott says, “As a woodworker with a passion for small electronics and computers, combining the two was a natural step.

Like many, this hobby has grown into an obsession and a business. I credit ShopBot Tools for sparking this journey when

I bought my first machine in 2000. After 25 years, I sold that machine and upgraded to a ShopBot PRS Alpha in 2007.

Later, Centroid’s Acorn controller inspired another upgrade, transforming my then-12-year-old, outdated system into a

revitalized powerhouse. No regrets, no looking back! Alongside this, I’ve restored and converted two benchtop machines

to Centroid Acorn systems.”

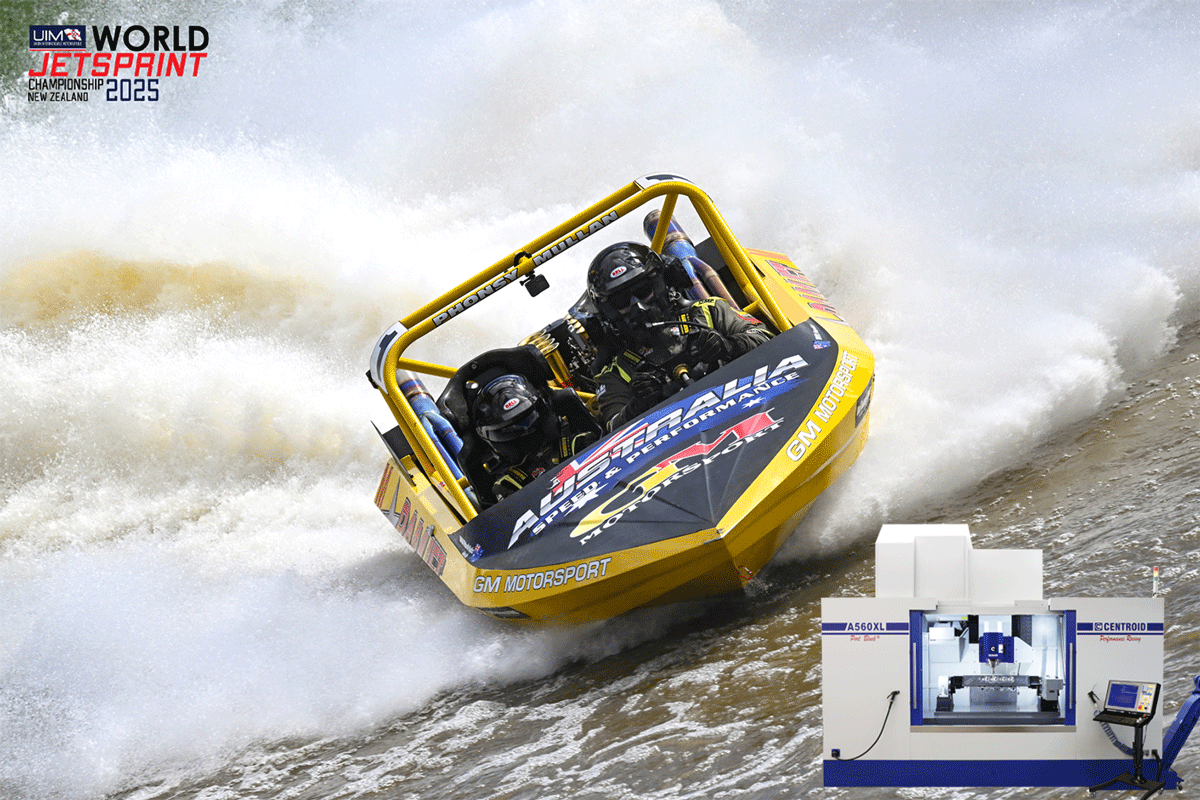

Congratulation to Centroid A560XL owner Phonsy Mullan!

Phonsy Mullan made jetsprint history by clinching the Triple Crown

in the Unlimited Premier Class, marking a world-first triple crown in jetsprint racing with his custom jet boat

CNC cylinder heads developed using the Centroid A560XL CNC cylinder head porting machine.

Learn more about the Centroid A560XL here!

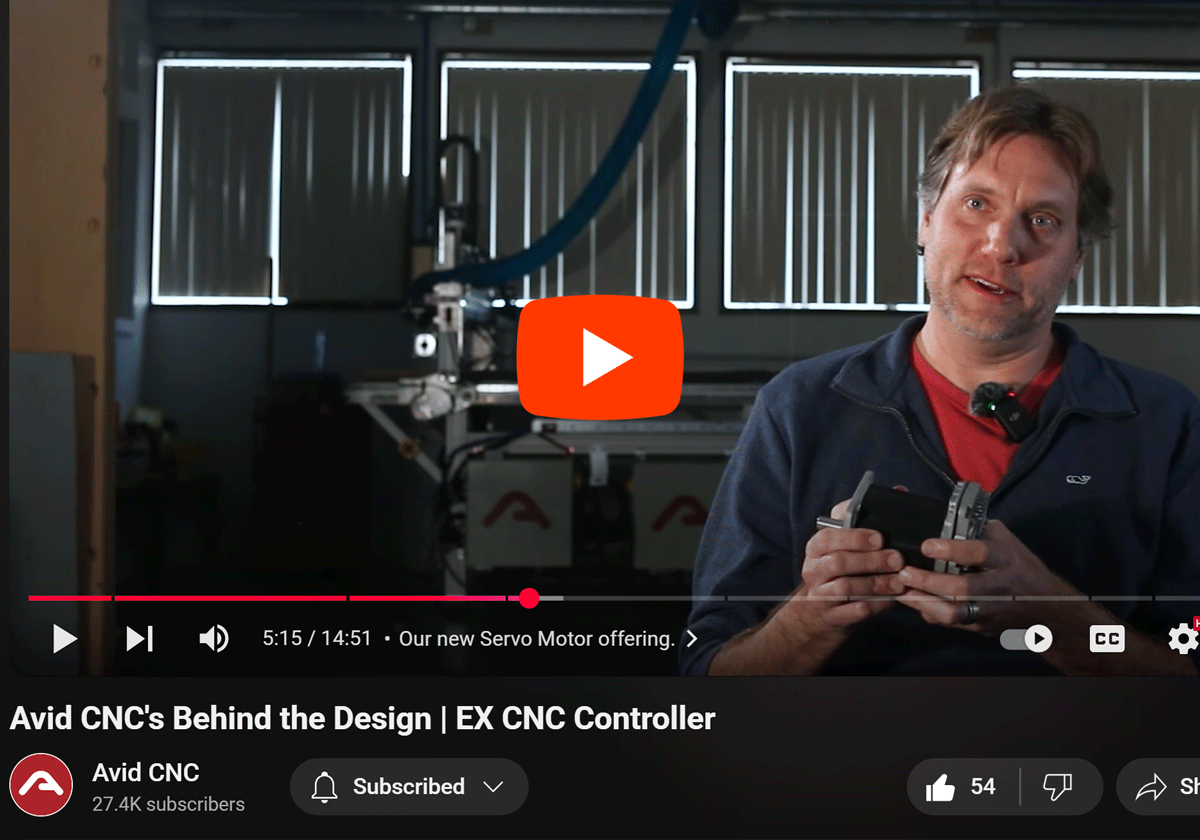

Why Centroid? Ahren talks about Avid’s new Centroid Acorn Based EX CNC controller and why they made the switch to Centroid Acorn/CNC12.

Watch the video here!

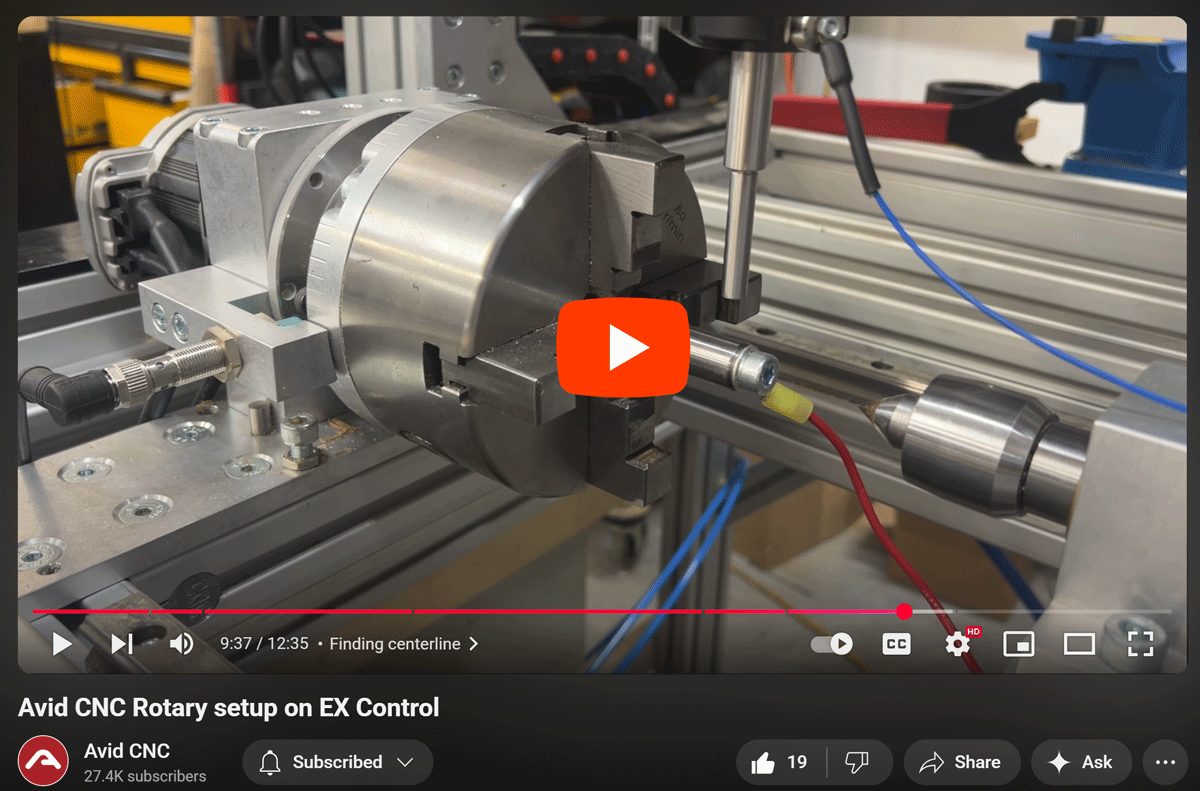

AvidCNC Rotary Setup on EX Control

Check out this great example of custom Centroid macro programming. With CNC12, any integrator, OEM,

or user can edit and tailor button macros to suit their unique application needs. AvidCNC has leveraged

the Centroid CNC12 customizable F key macros to create a semi-automatic CNC rotary table setup helper

which guides you thru the complete setup of a Rotary Table and Tail Stock on a CNC Router. These macros,

developed specifically by AvidCNC for their rotary setup, are included with their version of the CNC12 download.

Watch the video here!

Centroid CNC Controllers — Proudly Made in the USA!

Order Online, 24/7, at ShopCentroidCNC.com

In-Stock, Ready to Ship! Next-day order fulfillment on Acorn products and accessories.

World-Wide Shipping and unparalled CNC technical support.

Click here to browse ShopCentroidCNC.com

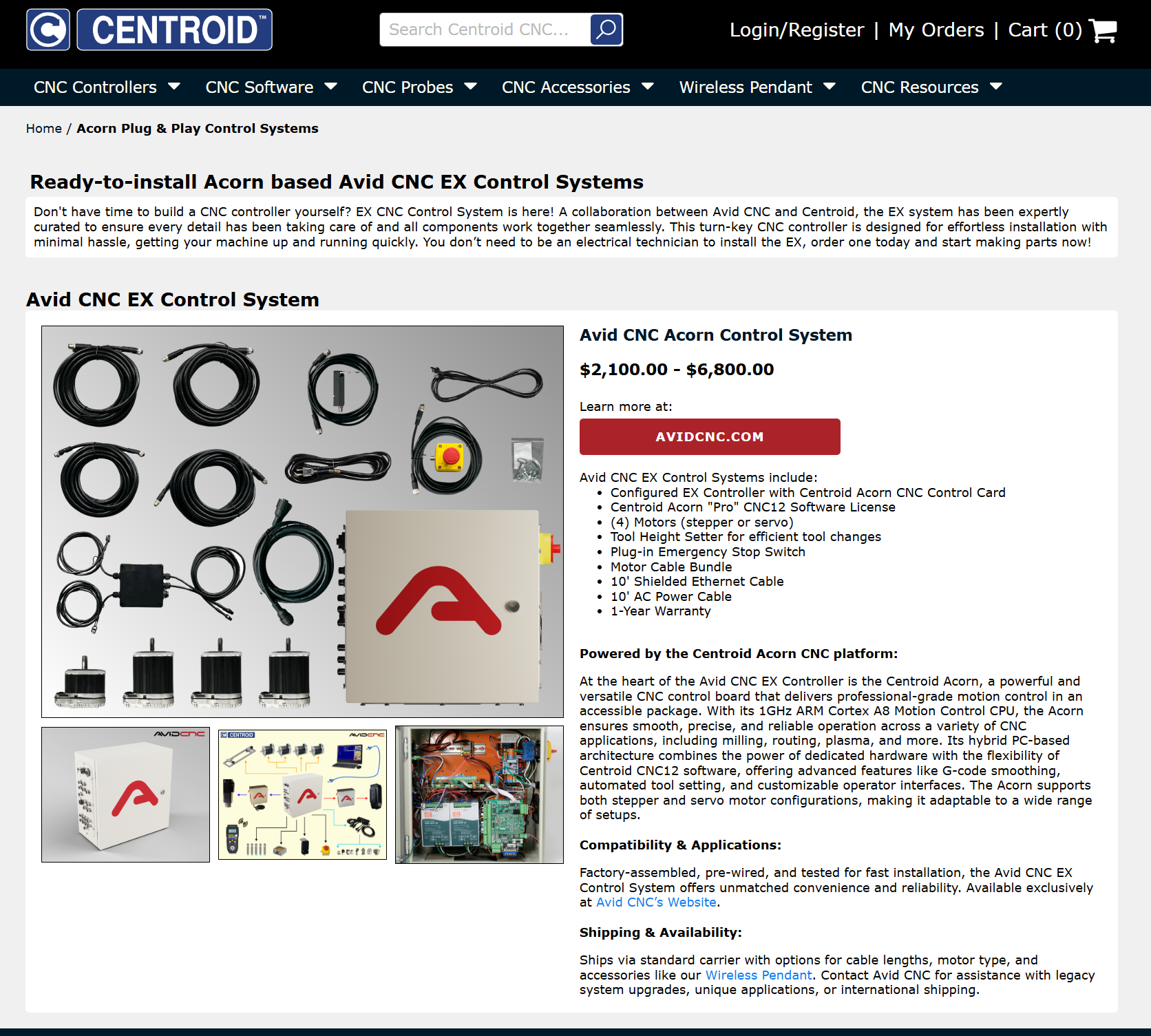

No time to build your own Centroid Acorn based CNC controller? AvidCNC turn-key EX pre-built CNC control systems are now available, configure and order online!

Click here to read more about the AvidCNC Ex Controller system!

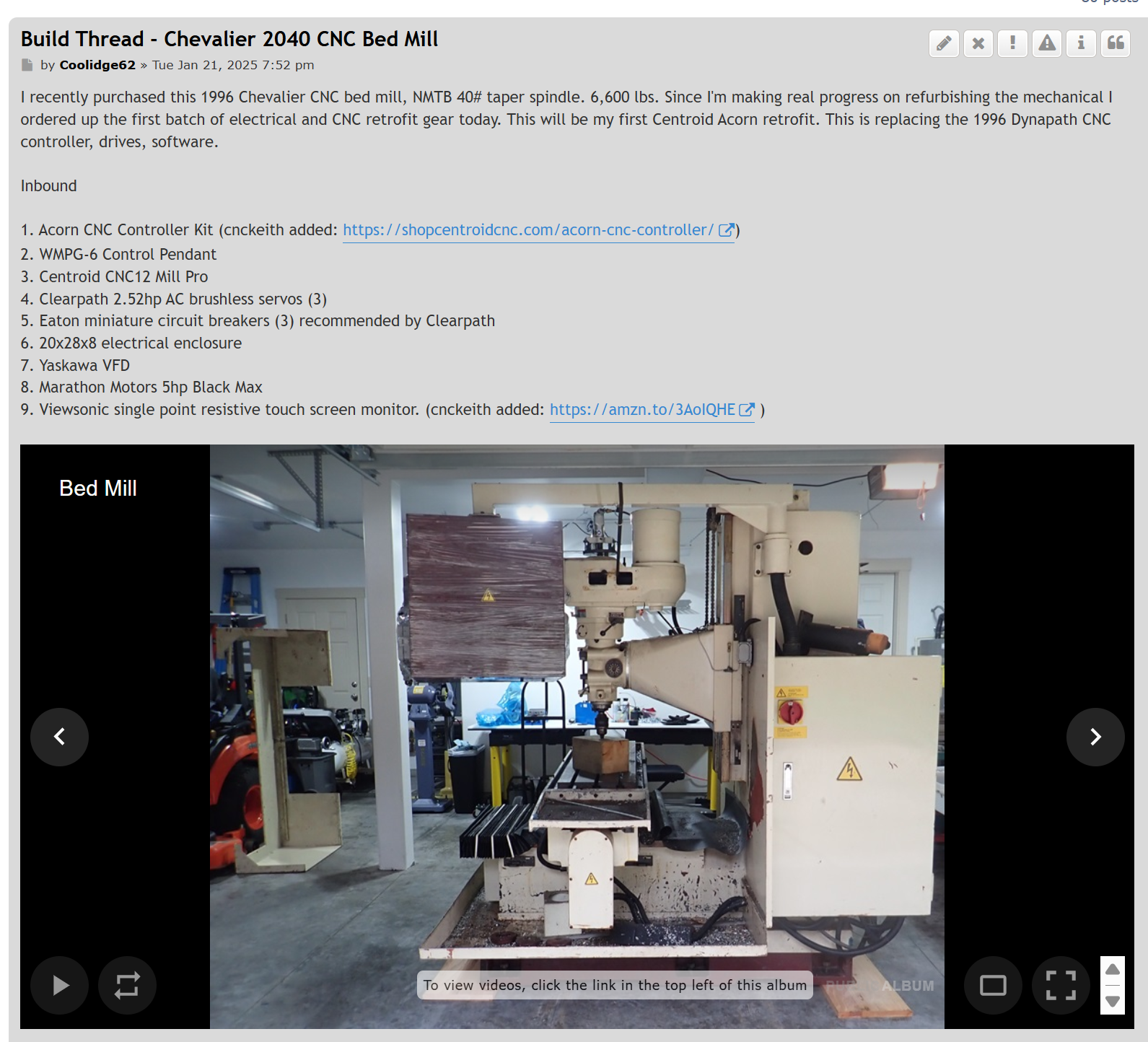

Centroid CNC Technical Support. What is a “Build Thread”?

Here is a great example of an on-going “Build Thread” located on the Centroid CNC Technical Support forum by Coolidge62

detailing the start to finish process of rebuilding and retrofitting a 1996 Chevalier 2040 CNC Bed Mill using the Made-in-USA

Acorn CNC controller and Clearpath servo motors.

View Coolidge62's Build Thread Here!

Creating a "build thread" on centroidcncforum.com offers several advantages for a customer, particularly those working on

CNC projects with Centroid products like the Acorn, AcornSix, USB-BOB,Hickory, Oak, or Allin1DC controllers. Based on the

forum’s structure and guidance, here’s why it’s beneficial:

- Organized Documentation: — A build thread consolidates all information, questions, and progress

about your CNC machine project into a single, cohesive post. Instead of scattering details across multiple threads or emails,

everything—from initial setup to troubleshooting—is in one place. This makes it easier for you and us to track your progress

and refer back to earlier steps or solutions.

- Timely CNC Technical Assistance: — The forum’s posting guidelines highlight that a build thread is "an

effective way to receive timely technical support." By keeping everything centralized, experts like moderators or other

power users can quickly spot where you’re at and offer targeted solutions, especially since Centroid staff actively monitor

the forum.

- Resource Centralization: — The forum encourages linking to a single photo album, YouTube channel, or

Google Drive folder within your thread. This keeps all visuals and files in one spot, making it easier for you to manage resources

and for others to follow along without sifting through attachments spread across multiple posts.

- Showcasing and Learning: — A build thread lets you document your journey start-to-finish, which can be

satisfying and educational. You can share successes (like completed retrofits, featured in the "Success Stories" section) and learn

from feedback. It also inspires others while allowing you to refine your approach based on community input.

- Better Support from the CNC Community: — The forum emphasizes that a build thread helps others understand

your project comprehensively. When you need help, responders (including Centroid staff and experienced users) can see the full

context—photos, specs, and prior issues—without you having to repeat yourself. This leads to faster, more accurate advice, as the

community doesn’t have to dig through disjointed posts to piece together your situation.

We invite you to make a build thread, here is how.

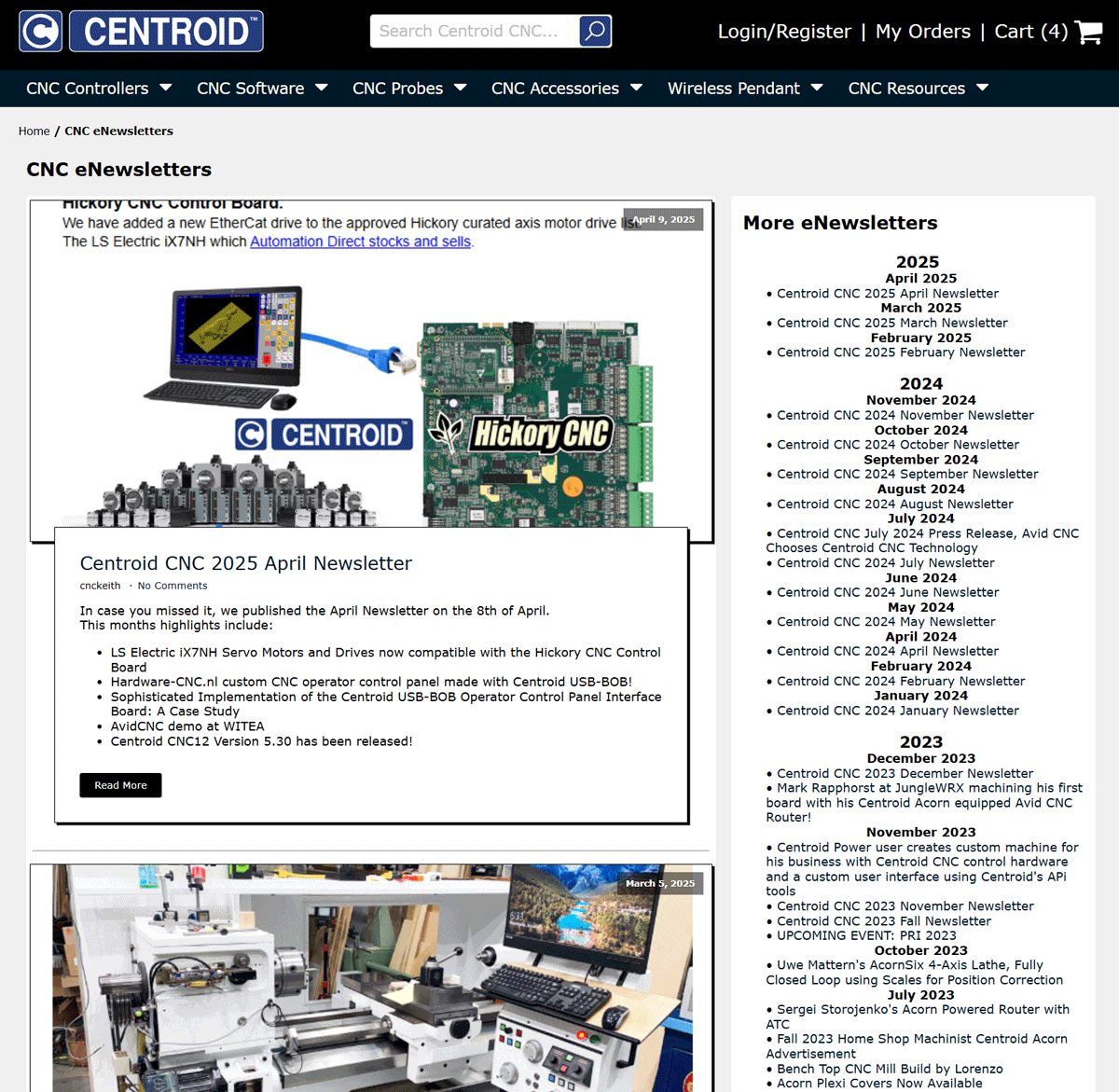

Did you miss out on last months CNC News?

‐ Centroid CNC Newsletter

back issues are here!

Catch up on our previous stories and insights by exploring the back issues of our CNC newsletter available

here!

|